The need for an extra Passivation of Stainless Steel.

An air- passivation of Stainless steels take place naturally on a clean surface. However in the presence of surface contamination, like free iron from contact with carbon steel tooling, this may interfere with the formation of the passive film. These contaminants has to be removed by using Passivator 630 to allow the oxygen uniform access to the surface in order to create the protective passive film. Further the air-passivation may take too much time in some aggressive environments, like close to the sea side. The passive film build up may need assistance of the Passivator 630 to speed up the formation.

A safer-to-use acid free Passivator!

Many of the processes used for passivation of stainless steel lead to the development of hazardous nitric fumes. We have developed a ONE Technology, to avoid this with a unique non fuming passivator which reduces the toxic nitric fumes by 100%.

Standard applications

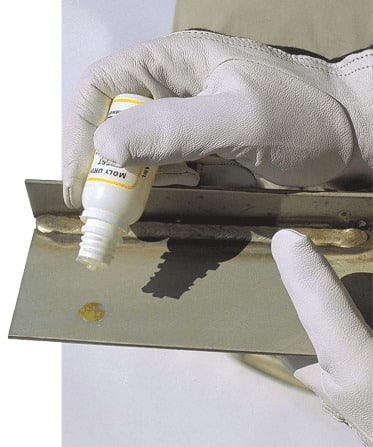

- The Passivator 630 restores stainless steel surfaces, after pickling or mechanical cleaning, that have been damaged during fabrication operations such as welding, forming, cutting and blasting. It removes free iron and speeds up the formation of the protective passive layer to prevent local corrosion. Avesta FinishOne Passivator 630 passivates without nitric or citric acid. This Passivator is acid free and safe to use. The resulting rinse water is acid free and hence no need for and extra neutralization and waste treatment step The Passivator 630 is intended for spray passivation only. For immersion or circulation passivation we recommend the Avesta 601 Passivator

Features

Provides a dual cleaning effect:

- ONE Technology, 100% NOx-reduction, this prevents the workers from breathing dangerous acid fumes.

- Higher yield, superior performances compared to nitric and citric acid passivation.

- Acid free, creates no toxic waste to handle, no risk for nitrates in the rinse water. Easy to handle and to ship, classified as non dangerous goods.

- Diminish the risk of discolored surfaces caused by flash clouds of free Iron (SMUT) when applied we-on-wet.

- For reduction of Nitric fumes during pickling by spraying a mist over the pickled surcafe “vet on wet”.

Packaging

Avesta FinishOne Passivator 630 is supplied in 25kg and 1000kg IBC polyethylene packages. Availability of different packages sizes may differ between markets.

Storage

Avesta FinishOne Passivator 630 should be stored indoors at room temperature. Containers must be kept

properlyclosed, in an upright position and inaccessible to unauthorized persons. Keep the lid on at all times when not in use. Metals, alkaline,organic materials, heat and UV radiation will degrade the product. Store in a clean, cool and UV protected environment. Avoid contact with textiles.

Maintenance Cleaning

To clean stainless steel objects in service afflicted by surface rust or tea staining, you can use Avesta Cleaner 401 in conjunction with Avesta FinishOne Passivator 630. This combination effectively eliminates surface rust and facilitates the regeneration of the stainless steel’s protective layer by accelerating the passive layer’s thickness.

Waste treatment

Empty containers made of HDPE should undergo a thorough cleaning process and subsequently be recycled in accordance with the applicable local regulations.

Reviews

There are no reviews yet.